Real-Time Transportation Visibility (Logistic Visibility Systems)

Whenever and wherever your supply chain is traveling, real-time visibility is the telescopic tower you can use to view its current state.

Speak With A Representative

Request Content Access

Our systems detected an issue with your IP. If you think this is an error please submit your concerns via our contact form.

- Products need to be delivered and received on time.

- Suppliers and distributors need to commit and adhere to agreements.

- Customers want to know where the product is at any given point in time.

- Companies need to be efficient as the cost of doing business has increased.

Our Advice

Critical Insight

- Almost 20% of shipments are impacted by congestion at ports and sourcing of transportation capacity.

- Within five years, over 80% of companies will be using cloud, sensors, inventory tools, and predictive or prescriptive analytics.

- Companies are shifting to more digital, direct sales, and partners to shore-up resiliency.

- Real-time visibility enables companies to see what’s happening throughout the supply chain and ensure that customer satisfaction is maximized.

Impact and Result

- Predict problems and identify opportunities to streamline processes.

- Enable higher levels of customer satisfaction.

- See how processes can be streamlined to meet OTIF targets.

Real-Time Transportation Visibility (Logistic Visibility Systems) Research & Tools

1. Real-Time Transportation Visibility (Logistic Visibility Systems) Storyboard

Use this research to gain insight into business requirements and the ways in which supply chain visibility (SCV) can benefit both you and your clients.

2. RACI – responsible, accountable, consult, and inform tool

Ensure that the right people are taking the correct actions at the correct time throughout the process.

3. Risk Prioritization tool

Use this tool to capture and prioritize any potential risks that may possibly upset your implementation.

Speak With A Representative

Request Content Access

Our systems detected an issue with your IP. If you think this is an error please submit your concerns via our contact form.

Available Soon

Webinar

Get on the Road With Real-Time Transportation Visibility

Check back soon to watch this webinar on demand.

Real-Time Transportation Visibility Systems

Whenever and wherever your supply chain is traveling, real-time visibility is the telescopic tower you can use to view its current state.

Analyst Perspective

You need to know where your products are, with who, the potential problems, and how to mitigate risks.

The capacity to track various items and/or products in transit, providing a clear picture of the inventory and activity, is known as supply chain visibility. With proactive status updates, management of inventory in motion, and information gathering from the entire supply chain, it helps shippers enhance customer service and control costs.

Using real-time information that identifies problems, a real-time supply chain visibility system assists you in identifying possible problems before they arise so that you can implement solutions that minimize risks and prevent potential disruptions.

The more sophisticated systems will combine data from all sources, both internal and external, spanning the whole supply chain service region. This includes data about people, processes, technology, and environmental factors like weather, road conditions, and other factors that could affect your product delivery services. These solutions also make use of machine learning and artificial intelligence to provide precise forecasts and recommended fixes.

Kevin Tucker

Principal Research & Advisory Director, Industry

Manufacturing, Supply Chain, Logistics, and Transportation

Info-Tech Research Group

Executive Summary

Your Challenge

Your supply chain stakeholders lack information, and they can't make rapid and/or accurate decisions in a timely manner.

You want to break down information silos to enable collaboration with employees, partners, and suppliers and ensure transparency with customers.

You have bad data that is incorrect, lagging, unreachable, and incomplete.

The systems and data aren't integrated and are causing all stakeholders to generate incorrect or incomplete decisions that are costly to the business.

Common Obstacles

The organization isn't capturing enough information for decision-making or it is capturing it all manually through spreadsheets and paper-based processes.

The business is used to doing things manually and views it as a good way to develop lasting relationships across all partners.

Consumers desire openness and speed in decision-making, but suppliers, employees, partners, and even customers themselves are reluctant to divulge information that they believe could inadvertently benefit rival businesses or other parties.

Info-Tech's Approach

Improve your supply chain visibility by using this research to understand the needs of the business and how SCV can help you and your customers.

Use our tools to evaluate your current state, identify software tools to help you elevate above your status.

Adopt a unified supply chain approach that considers a holistically interconnected environment for end-to-end capture of information for use with stakeholders.

We work closely with our customers to provide both strategic and tactical decision-making advisory services.

Info-Tech Insight

Supply chain complexity and volatility had risen rapidly through COVID-19, but it didn't level out after. Companies have become much more vigilant regarding the entire supply chain process. Visibility has become both a competitive advantage and critical for transparency across the supply chain network.

Transportation needs visibility of products in transit

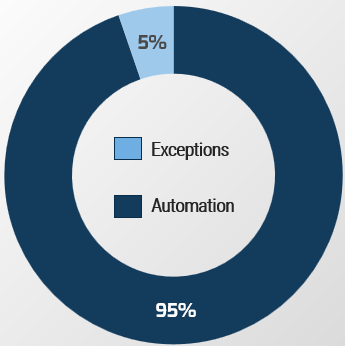

Automation and visibility are required across the supply chain:

Automate the capture and tracking of information related to the state and stage of goods in transportation across the supply chain.

Identify when real-time decisions are necessary to satisfy customer demands.

Automate to remove duplicate data and provide rapid automation for rate management including assessment, matching, and rejections.

Capture and manage information accurately across all modes of operation.

Being visible avoids the costs related to loss and spoilage of goods by operating punctually and allows you to enjoy the benefit of real-time location awareness.

Source: TMS First, 2023

Automation to Drive Visibility

Visibility elevates reliability and efficiency

Supply chain issues created a greater need for visibility

Goods must be accurately selected (picked) and safely loaded without any damage.

Monitor conditions to ensure there is no damage or spoilage of the goods being delivered.

Know where the goods are at any point throughout the journey between the different destinations.

Notifies key stakeholders about unplanned stops or the rationale for delays such as customs, queuing delays at security checkpoints, or excessive delays at loading docks.

Use environmentally friendly methods that customers increasingly demand.

Source: Route4me, 2022

Status Availability & Reliability Are Paramount for Customers

93% | Most customers want to know the progress of their goods throughout the delivery lifecycle from loading through until unloading from the delivery vehicle. Source: Route4Me, Rahul Dasgupta, 2022 |

|---|---|

47% | Customers want reliability. A large percentage of customers won't submit repeat orders with an unreliable brand. Source: Route4Me, Rahul Dasgupta, 2022 |

Track and trace through visibility

Stops & Delays

- Stops & Delays

Uses data and mobility for live tracking and tracing. - Customer Acceptance

Uses mobility to capture real-time proof of delivery. - On-Time Delivery

Tracks on-time delivery in full delivery success. - Driver Productivity

Conducts monitoring of service levels and driving habits. - Rejections & Claims

Immediate information about rejection reasons. - Performance Goals

Immediate access to real-time dashboards and alerts.

Source: Route4me, 2022, CH Robinson, 2023.

Visibility is formed through a vast Network of Information sharing

Info-Tech Insight

Every business will have their own platform design; however, all businesses will have similar kinds of actors to collaborate with through the implementation of networking technology.

Global visibility systems enhance integrated delivery

Streamline your processes and delight your customers

The System Is a Powerful Supply Chain Visibility Tower

Make the integration choice that is right for you

There are multiple dimensions to the visibility product decision-making process.

- Product visibility system selection: As a broker or manufacturer that needs to ship products for your business, or for your customers' businesses, you will need to identify the most appropriate visibility product for use within your business.

- Select integration that enhances full visibility: To have full visibility across your entire supply chain network you will need to be open to having API access to all your customers' individual visibility systems. You won't have a choice as to what systems they are using or how they will allow you to push information into their systems. This may require you to hire consultants or have internally skilled staff for conducting integration work.

Available Soon

Get on the Road With Real-Time Transportation Visibility

Check back soon to watch this webinar on demand.

Shreyas

Shukla

Principal Research Director Research - Development

Email Infographic

About Info-Tech

Info-Tech Research Group is the world’s fastest-growing information technology research and advisory company, proudly serving over 30,000 IT professionals.

We produce unbiased and highly relevant research to help CIOs and IT leaders make strategic, timely, and well-informed decisions. We partner closely with IT teams to provide everything they need, from actionable tools to analyst guidance, ensuring they deliver measurable results for their organizations.

What Is a Blueprint?

A blueprint is designed to be a roadmap, containing a methodology and the tools and templates you need to solve your IT problems.

Each blueprint can be accompanied by a Guided Implementation that provides you access to our world-class analysts to help you get through the project.

Talk to an Analyst

Our analyst calls are focused on helping our members use the research we produce, and our experts will guide you to successful project completion.

Book an Analyst Call on This Topic

You can start as early as tomorrow morning. Our analysts will explain the process during your first call.

Get Advice From a Subject Matter Expert

Each call will focus on explaining the material and helping you to plan your project, interpret and analyze the results of each project step, and set the direction for your next project step.

Unlock Sample ResearchAuthor

Kevin Tucker

Contributors

- Bob Verret, CIO, Dupre Logistics, LLC

- Michael O’Mally, Sales Development Representative, Project44

- Steven Schmidt, Managing Partner, Manufacturing and Transportation, Info-Tech Research Group

- Christopher Goodhue, Managing Partner, Manufacturing, Info-Tech Research Group

- Anonymous, Lead, Logistics Vertical

Unlock Real-Time Transportation Visibility (Logistic Visibility Systems)

Get Instant Access

Our systems detected an issue with your IP. If you think this is an error please submit your concerns via our contact form.

This content is exclusive to members.

Get instant access by signing up!

Our systems detected an issue with your IP. If you think this is an error please submit your concerns via our contact form.

Search Code: 104177

Last Revised: March 25, 2024

TAGS:

Real-time logistics tracking, visibility solutions for logistics, real-time supply chain monitoring, logistics visibility platforms, real-time freight tracking, visibility in transportation logistics, real-time inventory tracking, logistics tracking software, real-time shipment visibility, supply chain visibility solutions, real-time logistics management, visibility technology for logistics, real-time tracking and tracing, logistics visibility tools, real-time cargo monitoring, visibility and control in logistics, real-time warehouse tracking, logistics visibility services, real-time transportation visibility, visibility-enabled logistics systems.Book an Appointment

IT Research & Advisory Services

Our systems detected an issue with your IP. If you think this is an error please submit your concerns via our contact form.

%20%7C%20Info-Tech%20Research%20Group&_biz_n=11&rnd=582565&cdn_o=a&_biz_z=1744918546548)

%20%7C%20Info-Tech%20Research%20Group&rnd=665955&cdn_o=a&_biz_z=1744918546551)