This content requires an active subscription.

Contact one of our representatives for assistance.

+1-519-432-3550 (International)

Industry Insights Designed to Help You Lead Digital Transformation

With Info-Tech's Industry Roundtables & Benchmarking, you will never again wonder "what are my peers doing?", "how do I compare?", or "what should I be doing?".

Industry Insights & Best Practices

- Industry-Specific Research

- Reference Architectures

- Industry Trends

- Top Technologies

Executive Peer Groups

- Executive Collaboration

- Peer-to-Peer Knowledge Sharing

- High-Impact Discussion Topics

Industry-Specific Advisory Services

- Digital Transformation

- Linking Business & IT Value Maps

- Advisory Assistance to Help You Build Your IT Strategy

- Peer Benchmarking

Industry Roundtable Events

Non-Durable Goods - Critical Projects

Deep Insights Tailored to Your Industry

1

Business-Aligned IT Strategy

Understand the capabilities and focus areas required to meet your industry’s needs and enable value creation.

2

Top Industry Trends

Identify resource, process, and environmental trends impacting your industry. Implement strategies to mitigate specific risks and take advantage of all relevant opportunities.

3

Industry Benchmarking

Reveal the true state of your IT services, processes, spend, and staffing levels to align your priorities and resources. Benefit from peer data to get a reference point for how well you stack up.

4

Core Industry Technologies & Software Selection

Arm yourself with everything you need to provide the right solutions to meet the needs of your business stakeholders.

1

Business-Aligned IT Strategy

Strategy Alignment

Understand Modern Cybersecurity Solutions for Manufacturing IT & OT

- Info-Tech recognizes the role of CIOs in safeguarding smart factories. This research aims to empower CIOs with the knowledge and tools necessary to respond to immediate threats, anticipate and neutralize potential vulnerabilities, and secure a competitive advantage for their organizations.

- Info-Tech will provide:

- A comprehensive guide explaining the integration of cybersecurity measures and technologies into the design and operation of smart factories.

- A tool to help you assess cybersecurity risk across manufacturing operations including production lines, IT/OT networks, data storage areas, and supply chain interfaces.

Strategy Alignment

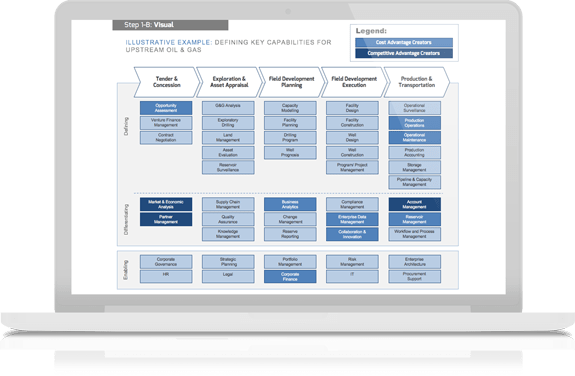

Non-Durable Goods Manufacturing Industry Reference Architecture

- Identify the kinds of applications and processes that would be impacted by changes.

- Prioritize mapping the capabilities.

- Align your staff with the capabilities map.

Strategy Alignment

Improve OT Governance to Drive Business Results

- Identify: Discover the methods, people, tools, and approaches that can be used to ensure you have a streamlined OT governance model in place.

- Prioritize: Further determine a tiered approach to assembling teams and tools.

- Align: After establishing your teams and understanding your gaps you will have a systematic approach for pulling in the right people with the right tools at the right time. Operations and IT will be tightly aligned.

Strategy Alignment

Priorities for Adopting an Exponential IT Mindset in the Non-Durable Goods Manufacturing Industry

- Recognize the urgency of adopting Exponential IT within the non-durable goods manufacturing industry to combat industry disruptions.

- Comprehend the four priorities of Exponential IT transformation in the non-durable goods manufacturing industry that are being adopted today to remain competitive within the market.

- Acknowledge the foundational capabilities and maturity required to begin an effective Exponential IT transformation, resulting in value creation.

Strategy Alignment

Transform Manufacturing by Mitigating the Challenges of Industry 4.0 and 5.0

Manufacturers have realized that successfully adopting Industry 4.0 and 5.0 technologies is essential to remain competitive. From incorporating principles of circularity to reducing costs and and controlling emissions, emerging technologies will have a transformative impact on the industry.

Info-Tech will provide:

Strategy Alignment

How CIOs Can Get Manufacturing Demand Planning Right

Improving demand planning has an impact on both the top-line and bottom-line.

Strategy Alignment

Non-Durable Goods Manufacturing Business-Aligned IT Strategy

- Learn about the ecosystem factors that are impacting the non-durable manufacturing industry and how your IT team is set from a PESTLE and SWOT perspective, with expert insights and takeaways to update your IT strategy.

Strategy Alignment

Non-Durable Goods Manufacturing IT Strategy Initiatives Workbook

- With input from our research and analysts and your peers, identify new or updated initiatives for your IT strategy.

- Working with our team, update your IT Strategy Initiatives Workbook.

Strategy Alignment

Non-Durable Goods Manufacturing Industry Impacts on IT Strategy: Senior Management Presentation Template

- Once you’ve completed the IT Strategy Initiatives Workbook, it’s time to pull it all together and share with your organization’s leadership team.

- Use the Non-Durable Goods Manufacturing Industry Impacts on IT Strategy: Senior Management Presentation Template to highlight the key findings from the business-aligned analysis you’ve done.

2

Top Industry Trends

Top Trends

Ensure Your Products Have a Compliant Manufacturing Supply Chain

- Identify: Understand the compliance, certifications, standards, and regulatory activities that are important for your business sector and products.

- Prioritize: Further determine which tools can be used for tracking and tracing information for conducting internal audits and generating reports for governing bodies.

- Align: After establishing what technologies are needed for compliance, form the team in accordance with initial setup and ongoing management of compliance across all suppliers as well as considerations for management of in-transit control processes such as customs and CTPAT.

Top Trends

Generative AI Use Case Library for the Non-Durable/Consumer Packaged Goods Manufacturing Industry

Info-Tech’s use case library provides practical guidance to help manufacturers accelerate value-driven Gen AI use case adoption.

Top Trends

Non-Durable Goods Manufacturing Shifting Demographics and Sustainability Report

- Market changes are creating new consumer trends and forcing companies to re-think their entire supply chain

- Learn about how shifting demographics affects both your organization and IT specifically, including challenges and opportunities, with expert assistance.

Top Trends

Non-Durable Goods Manufacturing Digitization Through Advanced Analytics Report

- Advanced analytics can sustain data-driven decisions and will be key for organizations to remain viable.

- Learn about how advanced analytics affects both your organization and IT specifically, including challenges and opportunities, with expert assistance.

Top Trends

Non-Durable Goods Manufacturing Attracting and Retaining Talent Report

- In non-durable manufacturing, there is a need to re-train personal or attract a different type of talent that is often hard to find.

- Learn about how Attracting and Retaining Talent affects both your organization and IT specifically, including challenges and opportunities, with expert assistance.

3

Industry Benchmarking

Peer Benchmarking

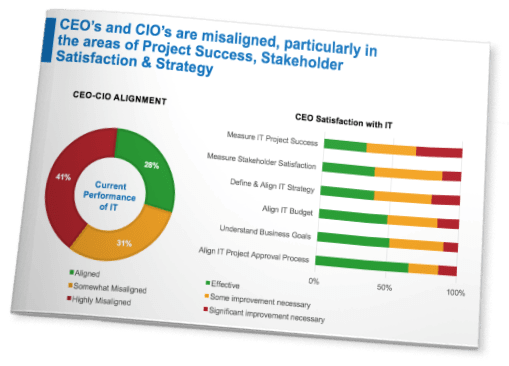

Benchmarking Report: A Cross-Industry Comparison of IT Stakeholder Satisfaction

- Every industry has unique characteristics that can hamper progress or facilitate success in satisfying IT stakeholders. Reimagine your strategy by shifting the definition of who your peers really are.

- Discover which industries achieve high stakeholder satisfaction across 13 core IT services.

- Learn the characteristics that different industries have that can help or hinder IT success.

- Understand what your industry has in common with others that you can leverage to improve stakeholder satisfaction and overcome your own institutional barriers.

Peer Benchmarking

Non-Durable Goods Manufacturing IT Stakeholder Satisfaction Benchmarking Report

- IT leadership needs to understand where their clients are unsatisfied with the quality of service they are receiving from IT.

- IT and OT departments need to develop closer governance models and share knowledge to leverage the benefits of many of the new technologies emerging in the sector.

- Understand important focus areas to address and insights into how your team compares with other Non-Durable Goods Manufacturing IT organizations.

Peer Benchmarking

Non-Durable Goods Manufacturing IT Staffing Benchmarking Report

- Many IT departments are already running lean, struggling to keep pace with never-ending demands from the business to be a reliable operator and effective partner, all while finding time and resources to be innovative.

- Manufacturing environments tend to have very low staff turnover. While this appears to be a positive on the surface, it can be a sign of stagnation and failure to bring in new skills.

- By taking the IT Staffing Diagnostic and participating in our unique IT Spend Benchmarking, you will gain critical insights to position your IT team to be more strategic.

Peer Benchmarking

Non-Durable Goods IT Management & Governance Benchmarking Report

- Understanding your IT team’s perception of what’s important and how well they’re doing is central to identifying strengths, weaknesses, and potential misalignments with business priorities and expectations.

- Learn about how IT departments in your industry assess the importance and effectiveness of 45 IT processes to gauge your own alignment and identify select processes for targeted improvement.

4

Core Industry Technologies & Software Selection

Core Industry Technologies

Real-Time Transportation Visibility (Logistic Visibility Systems)

- Predict problems and identify opportunities to streamline processes.

- Enable higher levels of customer satisfaction.

- See how processes can be streamlined to meet OTIF targets.

Core Industry Technologies

Harmonizing Complexity: Control Tower Integration

- Predict potential problems and identify corrective action.

- Enable higher levels of customer and employee satisfaction.

- See how effective the processes are in real-time.

Core Industry Technologies

Bring Your Factory to Life With Smart Manufacturing 5.0

- Predict any potential problems or roadblocks.

- Enable higher levels of collaboration and quality.

- See greater efficiency and customer satisfaction.

Core Industry Technologies

The Connected Factory

- Identify: The kinds of compliance, certifications, standards, and regulatory activities that are important for your business sector and products.

- Prioritize: Further determine which tools can be used for tracking and tracing information, for conducting internal audits, and for generating reports for governing bodies.

- Align: After establishing what technologies are needed for compliance you will form the team in accordance with initial setup and ongoing management of compliance across all suppliers as well as considerations for management of in-transit control processes such as customs and CTPAT.

Core Industry Technologies

Using Supply Chain Control Tower for Competitive Differentiation

A supply chain control tower allows organizations to:

- Predict problems across the supply chain.

- Enable real-time information and decision-making capabilities.

- See where goods are and any bottlenecks that may be occurring.

Core Industry Technologies

Deliver Operational Efficiency Through Predictive Maintenance

- Predict: problems based on tolerance.

- Enable: proactive actions (predictive instead of reactive maintenance).

- See: prevention of downtime, increased productivity, and higher customer satisfaction.

Core Industry Technologies

Autonomous Technologies in Manufacturing

The deployment of industrial robots in manufacturing can yield a wide range of impactful results, transforming various aspects of operations, productivity, and overall business success. Some potential results and impacts include:

- Enhanced Productivity: Industrial robots can perform tasks with high precision and consistency, leading to increased production speed and reduced cycle times. This heightened productivity can result in greater output and quicker order fulfillment.

- Improved Quality: Robots execute tasks with minimal variation, resulting in consistent product quality and reduced defects. This leads to improved customer satisfaction, reduced rework, and decreased waste.

- Optimized Resource Utilization: Robots can operate 24/7 without breaks, minimizing idle time and maximizing resource utilization. This efficiency leads to reduced energy consumption, optimized material usage, and improved overall resource management.

- Increased Flexibility: Modern robots are designed for versatility and easy reprogramming. Manufacturers can swiftly adapt to changes in production demands, allowing for rapid product line reconfiguration.

- Human-Robot Collaboration: Collaborative robots (cobots) can work safely alongside human operators, enhancing task efficiency and worker safety. This collaboration can lead to improved ergonomic conditions and reduced human fatigue.

- Data-Driven Decision-Making: Robotic automation generates vast amounts of data that can be analyzed to identify patterns, optimize processes, and make informed decisions for continuous improvement.

- Safety Improvement: Dangerous and hazardous tasks can be assigned to robots, reducing the risk of workplace accidents and injuries for human workers.

- Cost Reduction: While the initial investment in robotics can be substantial, the long-term cost savings from increased efficiency, reduced waste, and lower error rates can be significant.

- Competitive Advantage: Companies that embrace industrial robots can gain a competitive edge by offering higher-quality products, faster turnaround times, and improved customer responsiveness.

- Sustainability: Efficient resource utilization and waste reduction achieved through robotic automation can contribute to improved sustainability efforts, leading to reduced environmental impact.

Core Industry Technologies

Generative AI in Digital Twins

The deployment of Gen AI with digital twins can empower manufacturers with predictive insights and real-time solutions. Manufacturers can improve their operational efficiency, innovation capabilities, and overall competitiveness using cognitive twins. Gen AI also improves resilience, risk management, and sustainability when used in conjunction with digital twins.

- Enhanced Analytics: Predict future states of the system and identify potential issues or failures.

- Optimized Performance: Optimize system and process performance, resulting in improvements.

- Improved Decision-Making: Create new, innovative designs and solutions, resulting in novel products and services.

- Improved Resilience: Enhance supply chain visibility and predict potential disruptions.

- Sustainability and Waste Reduction: Reduce waste and energy consumption, leading to more sustainable operations.

- Rapid Changes: Enable digital twins to adapt in real-time to changes in the environment.

- Risk Management: Assess and simulate various risk scenarios, enabling proactive risk management.

- Improved Modeling: Create accurate simulations of complex systems to develop and test new concepts quickly.

Core Industry Technologies

Empower Your Manufacturing Organization With the Potential of Intelligent Automation

Intelligent automation adds significant value to organizations. Intelligent automation has a variety of real-world applications and can simplify processes, reduce resource use, and improve operational efficiencies.

- Extend and speed up innovation, automate R&D, and integrate products and services.

- Streamline supply chain operations and enable access to accurate information.

- Improve customer experience by automating sales, services, and marketing.

- Streamline core corporate processes across finance, sales, HR, and IT.

Core Industry Technologies

Digital Twins in Manufacturing

Embracing digital twin technology in the manufacturing industry offers a myriad of advantages, including:

- Enhanced Product Development: Digital twins enable rapid prototyping and virtual testing, reducing the time and costs associated with physical prototypes.

- Optimized Production Processes: Manufacturers can simulate different production scenarios to identify bottlenecks, optimize workflows, and improve overall efficiency.

- Predictive Maintenance: Digital twins facilitate predictive maintenance by analyzing real-time data, allowing businesses to address maintenance needs before equipment failure occurs.

- Reduced Downtime: With real-time monitoring and predictive capabilities, digital twins help minimize unplanned downtime, leading to increased productivity.

- Improved Quality and Safety: Manufacturers can ensure product quality and safety by identifying and rectifying issues in the virtual environment before they manifest in the physical world.

- Informed Decision Making: Data-driven insights from digital twins empower manufacturers to make well-informed decisions, driving continuous improvement.

- Remote Monitoring and Control: Digital twins enable remote monitoring and control of assets and processes, enabling efficient management across distributed locations.

Core Industry Technologies

Sustainable Autonomous Packaging Solutions

Failure to define and meet sustainability goals will mean:

- Significant reputational damage in addition to fines and legal action

- Inability to remain competitive in an evolving marketplace

- Being a less attractive option for customers actively looking for more sustainable solutions

Core Industry Technologies

Adopt Blockchain for Supply Chain Transparency

- Distinguish blockchain from bitcoin by introducing a business-centric definition of blockchain around its unique and competitive technological features.

- Discover successful blockchain use cases in different industries; business leaders can leverage tangible real-life examples to interpret the impact of blockchain on their own industry.

- By analyzing the value chain of their business, CIOs can understand stakeholder pain points and craft a blockchain use case around them.

Core Industry Technologies

Advanced Inventory Management

Effective, technology-led inventory management can help address supply chain challenges. This research presents a playbook to deploy advanced technology and improve your inventory management maturity. Critical components of this playbook include an overview of inventory management systems and their advanced capabilities, an introduction to KPIs for effective performance management, and a technology maturity map to show you what good inventory management looks like. This will ultimately arm you with the ability to plan better, procure more efficiently, and fulfill in an optimized manner across more channels, customer types, and geographies.

Core Industry Technologies

Non-Durable Goods Manufacturing Talent Management Technology Report

- A talent management system looks at the complete spectrum, from employer, to employee, to job dynamics.

- Learn about what talent management technology is, the state of the market, key features and functions, and leading vendors in the space in order to understand how it can transform your IT strategy and ability to deliver.

Core Industry Technologies

Non-Durable Goods Manufacturing Execution Systems Report

- The implementation of manufacturing executive systems adds a new level of visibility to the shop floor and overall equipment utilization.

- Learn about what manufacturing execution systems are, the state of the market, key features and functions, and leading vendors in the space in order to understand how they can transform your IT strategy and ability to deliver.

Core Industry Technologies

Non-Durable Goods Manufacturing Business Analytics Report

- As technology lowers barriers to entry, organizations are adopting business analytics to cope with the increased competition.

- Learn about what business analytics are, the state of the market, key features and functions, and leading vendors in the space. Understand how these can transform your IT strategy and ability to deliver.

Latest Non-Durable Goods Notes

Short, tailored research notes aimed at providing you with timely insights, relevant to your industry. Hot off the press, these notes will be published regularly and pair great with your morning coffee.

Meet the Manufacturing Sector Executive Services Leadership Team

November 7, 2023

Manufacturing is big business for Info-Tech, and so is our dedicated Manufacturing research and advisory services team’s ambition: Ensure that our members in manufacturing companies consistently receive exceptional value from their investment with Info-Tech! We do that by providing material, ongoing support for IT leaders in manufacturing on key IT initiatives, personal/professional development, peer networking, and career advancement.

Manufacturing: Advice From the COVID-19 Roundtable

March 30, 2020

On March 24, 2020, Info-Tech’s industry practice hosted a Manufacturing Industry Roundtable with the specific focus of identifying the impact that the COVID-19 pandemic is having in the industry. This is a summary of the roundtable discussions around three key issues.